Welcome to Channel-tube

Welcome to Channel-tube

LOW PRICE WITH GOOD QUALITY

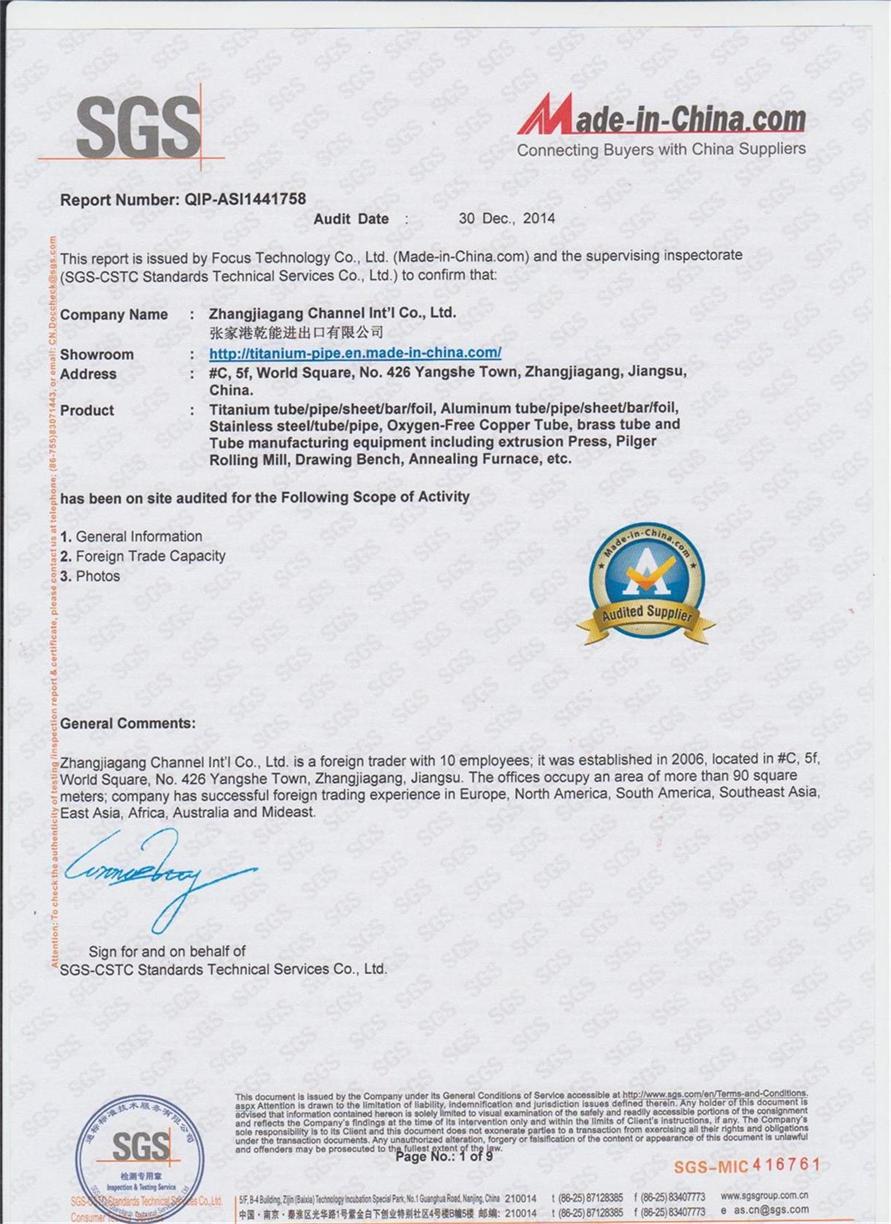

ISO Audited company.

We offer competitive price with best service.

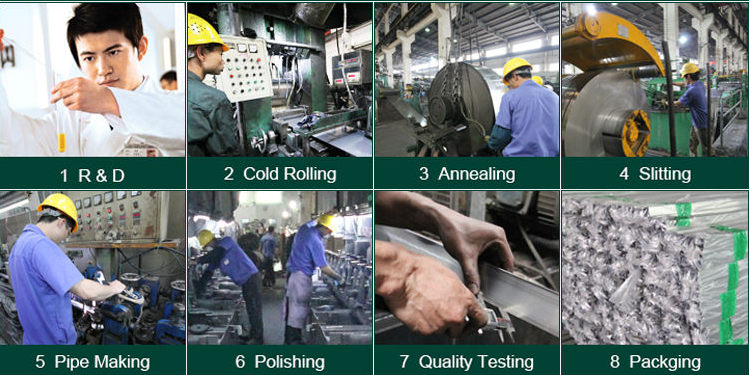

We can provide stainless steel processing services.

We have win high reputation based on best quality products.

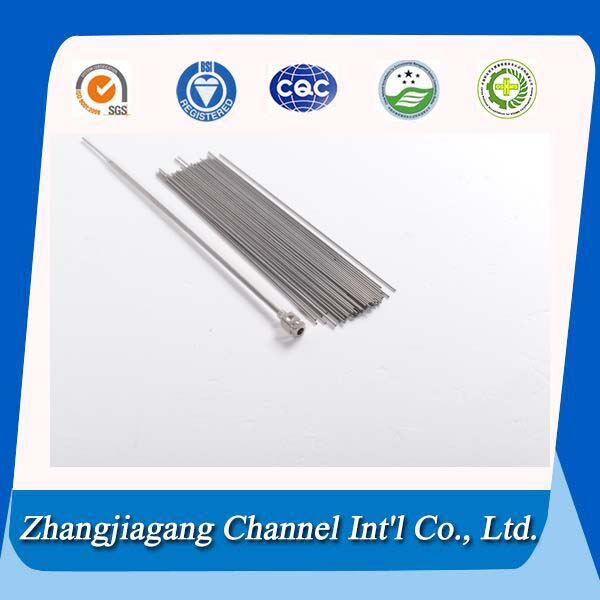

| Item | Stainless steel tube/tubes/tubing Stainless steel pipe/pipes | |

| Material | Stainless steel | |

| Grade | 201 (1Cr17Mn6Ni5N) 202(1Cr18Mn8Ni5N) 304(0Cr18Ni9) 304L(00Cr18Ni10) 306(0Cr17Ni12Mo2) 316L(0Cr17Ni14Mo2) 321, 409, 409L, 430 | |

| standards | ASTM, ASME,EN, JIS, DIN,GB/T etc | |

| Size | Outer Diameter:1mm-10mm; 10mm-250mm | |

| Wall Thickness: 0.01mm-4mm; 1mm-20mm | ||

| Length: 10mm -6000mm | ||

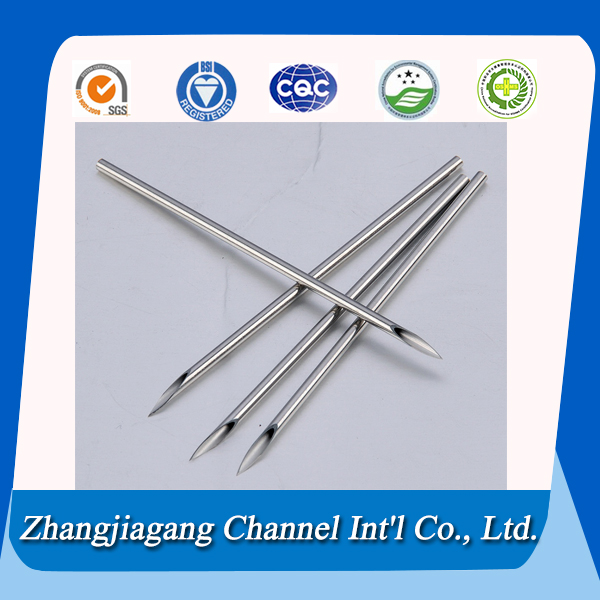

| Surface treatment | Polishing, Mirro surface, Bright, Pickling | |

| Type | Welded, ERW, seamless | |

| Manufacturing method | Hot rolled, Extrusion, Cold drawn, Cold rolled | |

| Shape | Round, Square | |

| Application | Architectural/Civil Engineer | Handrails, door and window fittings, steel furniture, structural sections etc |

| Transport | Exhaust systems, car trim, road tankers, ship containers, ships chemical tankers etc | |

| Chemical/Pharmaceutical | Pressure vessels, process piping etc | |

| Oil & Gas | Platform accomodation, cable trys, subsea pipelines etc | |

| Water | Water and sewage treatment, water tubing, hot water tankers etc | |

| Medical | Surgical instruments, surgical implanets, MRI scanners etc. | |

| Food & Drink | Catering equipment, brewing, food processing etc | |

| GradeC | C | Si | Mn | P | S | Ni | Cr | Mo | N |

| 201(1Cr17Mn6Ni5N) | ≤0.15 | ≤1.0 | ≤5.5 | ≤0.06 | ≤0.03 | 3.5-5.5 | 16.0-18.0 | — | ≤0.25 |

| 202(1Cr18Mn8Ni5N) | ≤0.15 | ≤0.07 | ≤7.5 | ≤0.06 | ≤0.03 | 4.0-6.0 | 17.0-19.0 | — | ≤0.25 |

| 3040Cr18Ni9) | ≤0.08 | ≤0.07 | ≤2.0 | ≤0.04 | ≤0.03 | 8.0-11.0 | 18.0-20.0 | — | — |

| 304L(00Cr18Ni10) | ≤0.03 | ≤0.07 | ≤2.0 | ≤0.04 | ≤0.03 | 8.0-11.0 | 18.0-20.0 | — | — |

| 316(0Cr17Ni12Mo2) | ≤0.08 | ≤0.07 | ≤2.0 | ≤0.04 | ≤0.03 | 11.0-14.0 | 16.0-18.0 | 2.0-3.0 | — |

| 316L(0Cr17Ni14Mo2) | ≤0.03 | ≤0.07 | ≤2.0 | ≤0.04 | ≤0.03 | 11.0-14.0 | 16.0-18.0 | 2.0-3.0 | — |

| 321 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.04 | ≤0.03 | 9.0-12.0 | 17.0-19.0 | | Ti≥5xC |

| 409 | ≤0.08 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | ≤0.5 | 10.5-11.7 | | Ti6xC%≤0.70 |

| 409L | ≤0.03 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | 0.5 | 10.5-11.7 | | Ti8xC%≤0.70 |

| 430 | ≤0.12 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | | 16.0-18.0 | | |

| ASTM | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elogation (%) | Hardness (HRB) |

| 201 | ≥655 | ≥310 | ≥40 | ≤100 |

| 202 | ≥620 | ≥260 | ≥40 | ≤100 |

| 304 | ≥515 | ≥205 | ≥40 | ≤92 |

| 304L | ≥482 | ≥170 | ≥40 | ≤88 |

| 316 | ≥515 | ≥205 | ≥40 | ≤95 |

| 316L | ≥485 | ≥170 | ≥40 | ≤95 |

| 321 | ≥515 | ≥205 | ≥40 | ≤95 |

| 409 | ≥380 | ≥205 | ≥20 | ≤80 |

| 409L | ≥350 | ≥185 | ≥22 | ≤80 |

| 430 | ≥450 | ≥205 | ≥22 | ≤80 |