Welcome to Channel-tube

Welcome to Channel-tube

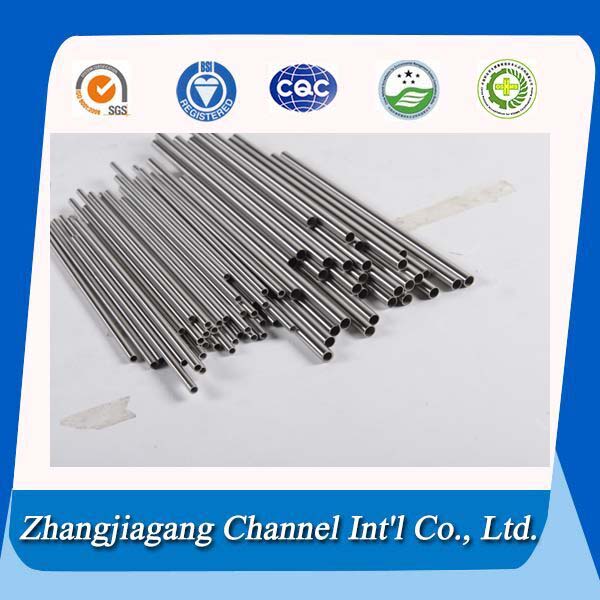

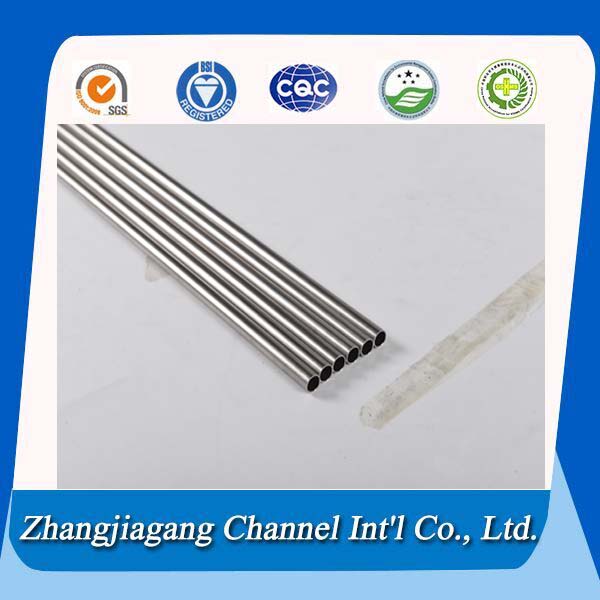

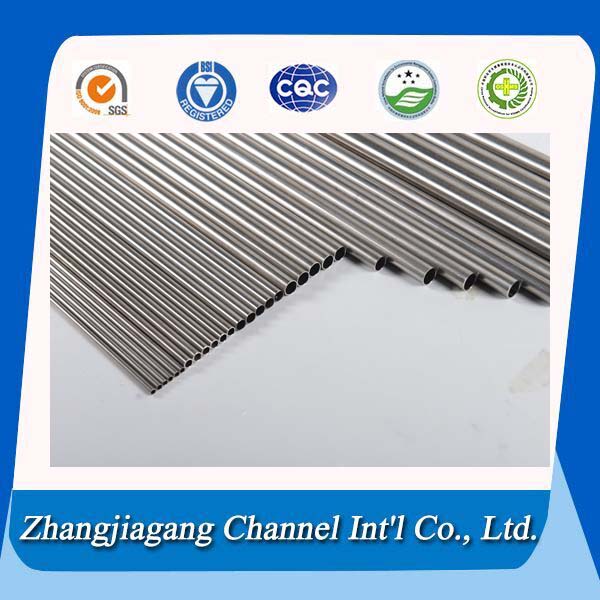

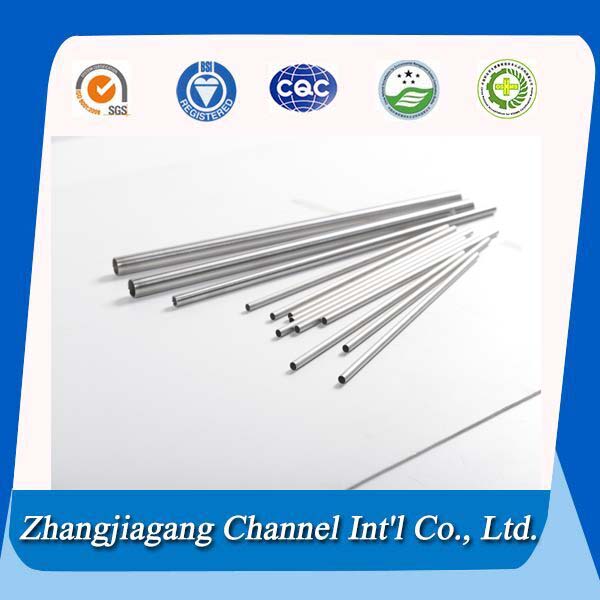

You can select different sizes of stainless steel pipes with high quality from a reliable supplier with reasonable price.

Size range: Out Diameter: 1mm-250mm

Wall thickness: 0.01-100mm

Certificated Supplier

| Item | Stainless steel tube/tubes/tubing Stainless steel pipe/pipes | |

| Material | Stainless steel | |

| Grade | 201 (1Cr17Mn6Ni5N) 202(1Cr18Mn8Ni5N) 304(0Cr18Ni9) 304L(00Cr18Ni10) 306(0Cr17Ni12Mo2) 316L(0Cr17Ni14Mo2) 321, 409, 409L, 430 | |

| standards | ASTM, ASME,EN, JIS, DIN,GB/T etc | |

| Size | Outer Diameter:1mm-10mm; 10mm-250mm | |

| Wall Thickness: 0.01mm-4mm; 1mm-20mm | ||

| Length: 10mm -6000mm | ||

| Surface treatment | Polishing, Mirro surface, Bright, Pickling | |

| Type | Welded, ERW, seamless | |

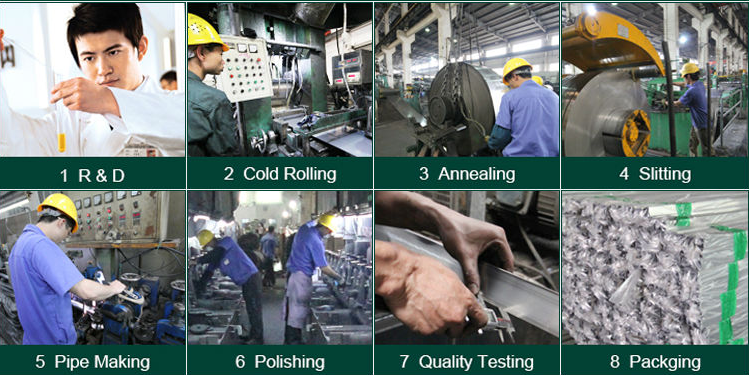

| Manufacturing method | Hot rolled, Extrusion, Cold drawn, Cold rolled | |

| Shape | Round, Square | |

| Application | Architectural/Civil Engineer | Handrails, door and window fittings, steel furniture, structural sections etc |

| Transport | Exhaust systems, car trim, road tankers, ship containers, ships chemical tankers etc | |

| Chemical/Pharmaceutical | Pressure vessels, process piping etc | |

| Oil & Gas | Platform accomodation, cable trys, subsea pipelines etc | |

| Water | Water and sewage treatment, water tubing, hot water tankers etc | |

| Medical | Surgical instruments, surgical implanets, MRI scanners etc. | |

| Food & Drink | Catering equipment, brewing, food processing etc | |

| GradeC | C | Si | Mn | P | S | Ni | Cr | Mo | N |

| 201(1Cr17Mn6Ni5N) | ≤0.15 | ≤1.0 | ≤5.5 | ≤0.06 | ≤0.03 | 3.5-5.5 | 16.0-18.0 | — | ≤0.25 |

| 202(1Cr18Mn8Ni5N) | ≤0.15 | ≤0.07 | ≤7.5 | ≤0.06 | ≤0.03 | 4.0-6.0 | 17.0-19.0 | — | ≤0.25 |

| 3040Cr18Ni9) | ≤0.08 | ≤0.07 | ≤2.0 | ≤0.04 | ≤0.03 | 8.0-11.0 | 18.0-20.0 | — | — |

| 304L(00Cr18Ni10) | ≤0.03 | ≤0.07 | ≤2.0 | ≤0.04 | ≤0.03 | 8.0-11.0 | 18.0-20.0 | — | — |

| 316(0Cr17Ni12Mo2) | ≤0.08 | ≤0.07 | ≤2.0 | ≤0.04 | ≤0.03 | 11.0-14.0 | 16.0-18.0 | 2.0-3.0 | — |

| 316L(0Cr17Ni14Mo2) | ≤0.03 | ≤0.07 | ≤2.0 | ≤0.04 | ≤0.03 | 11.0-14.0 | 16.0-18.0 | 2.0-3.0 | — |

| 321 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.04 | ≤0.03 | 9.0-12.0 | 17.0-19.0 | | Ti≥5xC |

| 409 | ≤0.08 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | ≤0.5 | 10.5-11.7 | | Ti6xC%≤0.70 |

| 409L | ≤0.03 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | 0.5 | 10.5-11.7 | | Ti8xC%≤0.70 |

| 430 | ≤0.12 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | | 16.0-18.0 | | |

| ASTM | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elogation (%) | Hardness (HRB) |

| 201 | ≥655 | ≥310 | ≥40 | ≤100 |

| 202 | ≥620 | ≥260 | ≥40 | ≤100 |

| 304 | ≥515 | ≥205 | ≥40 | ≤92 |

| 304L | ≥482 | ≥170 | ≥40 | ≤88 |

| 316 | ≥515 | ≥205 | ≥40 | ≤95 |

| 316L | ≥485 | ≥170 | ≥40 | ≤95 |

| 321 | ≥515 | ≥205 | ≥40 | ≤95 |

| 409 | ≥380 | ≥205 | ≥20 | ≤80 |

| 409L | ≥350 | ≥185 | ≥22 | ≤80 |

| 430 | ≥450 | ≥205 | ≥22 | ≤80 |